Lube Oil Testing Unit

LOTUS

LOTUS BEACON by Sensyn is state of the art, real-time oil condition monitoring system, engineered for continuous, inline measurement of critical parameters that directly impact machinery performance and reliability. Designed for harsh marine and industrial environments, BEACON delivers a comprehensive overview of oil health—helping operators make smarter, data-driven maintenance decisions without waiting for lab reports or shutdowns.

BEACON monitors oil degradation by tracking Base Number (BN) depletion, oxidation levels, and shifts in viscosity—providing insight into additive depletion and thermal stress over time. It detects oil contamination through changes in dielectric constant and density, identifying the presence of water, soot, fuel dilution, or cross-contamination with other fluids. Additionally, BEACON identifies machinery wear by capturing ferrous and non-ferrous wear debris in the oil, offering early indications of component fatigue, gear wear, or bearing issues before they escalate into failures.

Scrape Down Oil Testing Unit

IRIS

IRIS by Sensyn is a compact, high-precision diagnostic tool designed for rapid on-site analysis of ferrous wear particles in lubricants, coolants, and greases. Built for reliability in rugged environments, IRIS empowers maintenance teams with lab-grade analytics in the field—delivering accurate iron content readings in just one second using as little as 2 mL of oil. IRIS helps detect early-stage wear in components like bearings, gearboxes, and liners, making it an invaluable asset for wind turbines, marine engines, heavy industrial equipment, and remote installations.

Water-in-Oil Sensor for Critical Machinery

LOTUS-W

The Lotus-W by Sensyn is a compact, industrial-grade Moisture Content Sensor designed for real-time water detection in oils, helping to ensure equipment longevity and reliability across sectors like wind turbines, marine engines, industrial gearboxes, and hydraulic systems.

Traditional sampling methods are periodic and reactive. Lotus-W delivers continuous, real-time monitoring, allowing proactive maintenance actions before failure. It is plug-and-play, calibration-free, and requires no consumables, offering a low total cost of ownership.

Hydraulic Oil Particle Analyzer

HYDRA

Hydra by Sensyn is an advanced in-line particle monitoring system designed for real-time contamination analysis in lubricating and hydraulic oil systems. Using ISO-certified light-blockage (light-shading) technology, Hydra precisely detects solid particles as small as 1 µm, classifies them into multiple cleanliness standards (ISO 4406, NAS1638, GJB420B), and provides continuous insights into oil cleanliness levels. Whether it’s monitoring wind turbine gearbox oil, hydraulic circuits in manufacturing, or aviation-grade fluids, Hydra ensures predictive maintenance through precision data.

Vacuum Dehydration & Filtration System

ORCHID

Built for performance and sustainability, Sensyn Orchid keeps your oil clean, dry, and reliable.

Its intelligent purification system removes water, air, and contaminants through advanced vacuum and multi-stage filtration, extending oil life up to 5× while minimizing waste and downtime.

Seamlessly integrable with Lotus, Hydra and Aster, ORCHID turns oil maintenance into a smart, continuous, and cost-efficient process.

Software

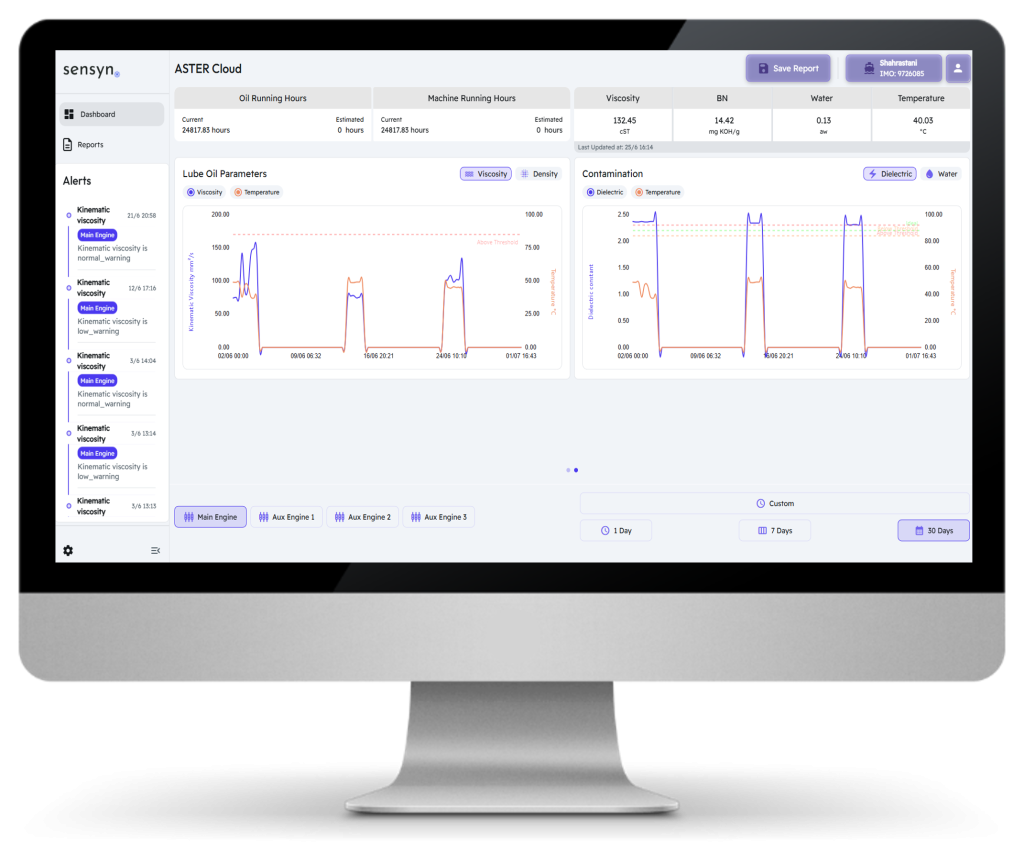

ASTER

ASTER by Sensyn is an integrated solution designed to revolutionize oil condition monitoring and fleet management. By seamlessly combining on-premises data acquisition, centralized control, and cloud-based analytics, ASTER delivers end-to-end visibility into vital machinery health parameters. Tailored for the maritime industry, ASTER bridges the gap between onboard systems and onshore decision-making, empowering stakeholders to make timely, data-driven decisions.