Real-Time Lube Oil Monitoring for Marine Vessels

The LOTUS Beacon is an innovative solution designed specifically for the maritime industry, offering continuous, real-time monitoring of lube oil quality onboard ships. By providing precise insights into oil condition, contamination levels, and machinery wear, LOTUS Beacon ensures that ship operators can take proactive maintenance actions, reduce unplanned downtime, and extend the life of critical equipment. With its robust design, intuitive user interface, and seamless connectivity, LOTUS Beacon is the ideal companion for maintaining optimal operational efficiency on the high seas.

Intuitive digital display easy monitoring

Consistent performance even Under extreme conditions

Status updates through Safety indicators

Direct connections to multiple Oil sampling points

LOTUS Beacon is a real-time, inline oil condition monitoring sensor designed to measure a comprehensive set of critical parameters. It accurately monitors

- Density (kg/m³),

- Viscosity (cSt),

- Water activity (aw),

- Moisture content (ppm),

- Wear debris (both ferrous and non-ferrous particles in counts),

- Temperature (°C),

- Dielectric constant.

These measurements enable early detection of oil degradation, contamination, and machinery wear—allowing operators to shift from reactive maintenance to predictive strategies.

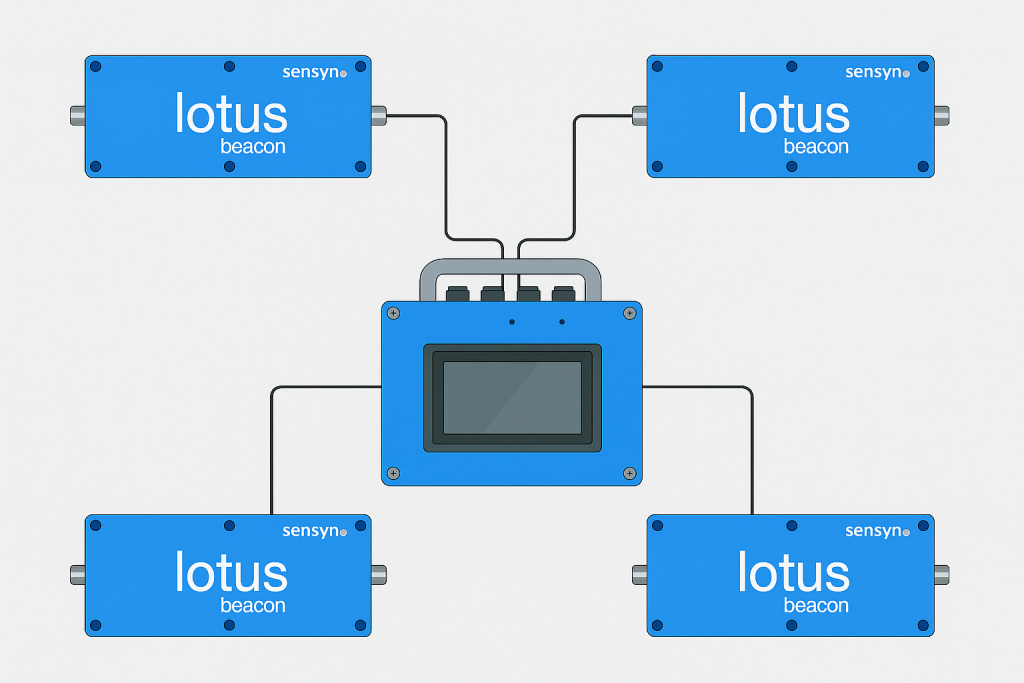

To complement the sensor system, the LOTUS Beacon JB (Junction Box) supports up to four LOTUS Beacons simultaneously. It features a 4-inch touchscreen display for live data visualization, supports RS485 and TCP output for seamless integration with SCADA or cloud systems, and includes a USB port for software updates. Together, the LOTUS Beacon and JB offer a scalable, plug-and-play solution for continuous fluid condition monitoring across multiple machinery assets.

Why Choose LOTUS

Real-Time Data Acquisition:

The LOTUS system delivers instant feedback on crucial oil quality parameters such as temperature, viscosity, density, and Total Base Number (TBN). This enables ship operators to stay ahead of potential issues and maintain machinery in peak condition, ensuring smooth operations even in the most demanding conditions.

Advanced Sensing Technology:

Featuring cutting-edge sensors, LOTUS precisely detects contamination indicators like moisture content, free water, and fuel dilution. Additionally, it monitors wear particles, including ferrous and non-ferrous debris, allowing for early detection of machinery wear and tear, thereby preventing costly breakdowns.

Durable Design for Marine Environments:

Built to withstand harsh maritime conditions, the LOTUS system is housed in an IP64- rated enclosure, offering protection against dust and water ingress. Constructed from high-grade materials like mild and stainless steel, it operates efficiently in a wide temperature range of -20°C to 60°C, making it resilient against the toughest environments at sea.

User-Friendly Interface:

The LOTUS control panel is designed with a clear digital display and a responsive touchscreen interface, making it easy to monitor key parameters and configure settings. The emergency stop button, and configurable alerts add an extra layer of operational safety, ensuring swift responses during critical situations.

Seamless Connectivity:

With built-in Ethernet, RS485 Modbus, and USB ports, LOTUS facilitates seamless data extraction and remote diagnostics. The system’s compatibility with Modbus RTU/TCP allows it to integrate smoothly with existing shipboard monitoring systems, ensuring that operators have access to real-time data, both onboard and ashore.