Inline Hydraulic Oil Particle Analyzer

HYDRA is a high-resolution, inline particle analyzer built for hydraulic and lubrication systems operating under extreme conditions. It utilizes light-blockage technology to detect and classify solid contaminants in real-time, ensuring compliance with international cleanliness standards and preventing premature equipment failure. Compact and industrial-grade, HYDRA is ideal for continuous monitoring in marine, wind, and factory applications.

Precision Oil Testing, Automated Excellence

Your Predictive Maintenance Partner

Consistent Insights, Enhanced Engine Longevity

Hydraulic Oil Testing for Reliable Performance

Using ISO-certified light-blockage technology, HYDRA detects and classifies solid particles down to 1 micron, delivering precise contamination data based on international standards like ISO 4406, NAS1638, and GJB420B. Compact and IP65-rated, HYDRA operates reliably in harsh environments, making it ideal for applications in wind turbines, marine engines, industrial hydraulics, and aerospace-grade systems.

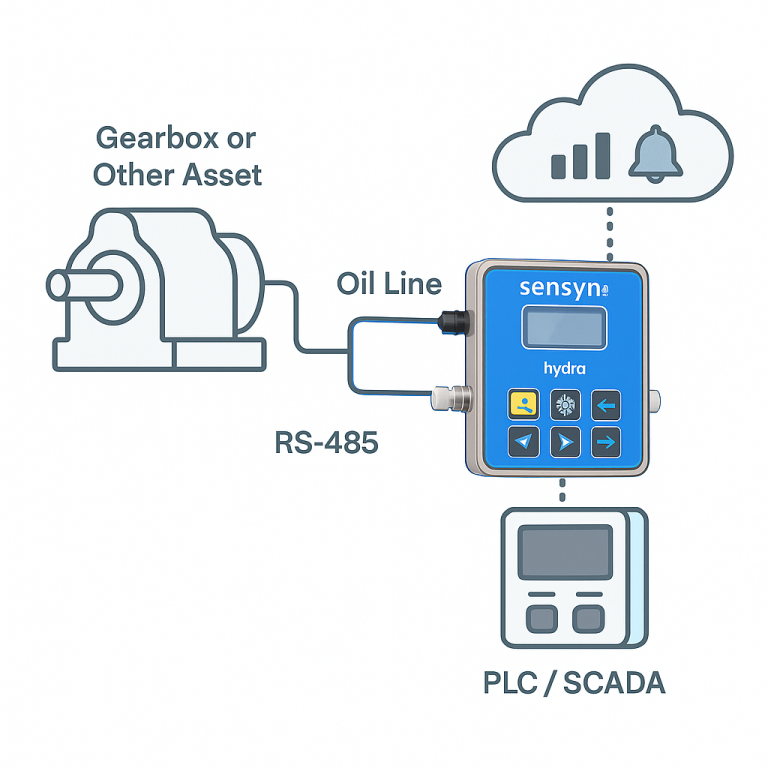

HYDRA supports RS-485 Modbus RTU output with optional 4–20 mA analog, and is optimized for flow rates of 10–300 mL/min with fast response times ranging from 5 to 60 seconds. With internal flow compensation, trend monitoring, and AI-powered cleanliness scoring, HYDRA transforms oil particle data into clear, actionable insights—ensuring operational reliability and efficiency.