Scrape down oil testing unit

Iron Detection for Scrap down Oil

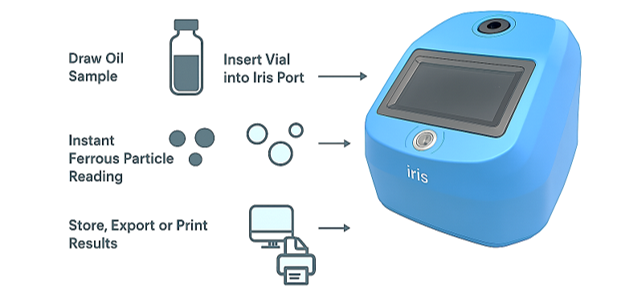

IRIS is Sensyn’s portable, high-precision diagnostic tool designed for quick, on-site detection of ferrous wear particles in lubricants, greases, and coolants. Built for rugged environments and ease of use, IRIS delivers lab grade insights in seconds—without the lab.

Precision Oil Testing, Automated Excellence

Your Predictive Maintenance Partner

Consistent Insights, Enhanced Engine Longevity

Faster Decisions: 10x faster than lab analysis

No sample prep.

No lab dependency.

Field-ready insights.

Why Choose iris

Real-Time, On-the-Spot Results

IRIS gives you immediate ferrous particle readings from just a 2 mL oil sample—no waiting, no lab required. Within seconds, maintenance teams can assess wear levels and make informed decisions, right at the equipment location.

Engineered for Harsh, Remote Environments

Compact, lightweight, and battery-powered, IRIS is built for field use whether on a ship at sea, inside a wind turbine nacelle, or at a remote industrial site. Its rugged design ensures reliable performance wherever insights are needed most.

Predictive Maintenance Made Simple

By detecting early signs of wear through ferrous particle monitoring, IRIS empowers operators to take proactive action before minor issues escalate. It helps extend equipment life, reduce downtime, and avoid costly repairs—all with minimal training or setup.