Our Technology

Sensors

SENSYN utilizes state-of-the-art sensors designed for precision and durability in extreme marine environments. These sensors provide real-time, continuous monitoring of lube oil parameters, including contamination levels, viscosity, water ingress, and wear debris. The high sensitivity and accuracy of the sensors ensure early detection of anomalies, helping protect critical machinery and extend equipment lifespan.

Software

The ASTER software is the brain behind the system, integrating advanced algorithms and machine learning to process sensor data. It delivers actionable insights through a user-friendly interface, offering predictive maintenance recommendations, automated reporting, and seamless integration with shipboard systems. The software simplifies operations for both onboard crews and shore management.

Analytics

Analytics is the cornerstone of SENSYN, transforming raw data into meaningful insights. The system employs ML-driven data models to detect trends, predict failures, and optimize RUL.. These analytics not only ensure the reliability of machinery but also provide cost savings by reducing unplanned downtime and improving operational efficiency.

Our Sensors

At Sensyn, we specialize in advanced oil condition monitoring sensors that combine proven sensing principles with rugged, field-ready engineering. Each of our sensors is designed to deliver real-time, inline insights into oil health eliminating the delays of traditional lab analysis and enabling predictive maintenance right where it matters most.

Electrical Capacitance:

We use capacitive sensor arrays to measure changes in the dielectric constant (ε) of the oil. Since water, fuel, and soot contamination have much higher dielectric properties than clean base oil, any increase in ε is a strong indicator of contamination or degradation. Additionally, our sensors measure water activity (aw) using relative humidity sensors embedded in oil-immersed capacitive structures, providing a direct indication of how close the oil is to reaching water saturation—critical for preventing emulsification and corrosion.

Magnetic Sensors:

For wear particle detection, Sensyn uses an inductive bridge sensing technique. As ferrous or non-ferrous particles pass through the sensor’s magnetic field, they create a measurable disturbance that allows us to count and classify them. This is crucial for early detection of abnormal component wear (bearings, gears, liners) and serves as a frontline indicator of mechanical stress before failure occurs.

Thermal Viscosity Sensing

To determine viscosity, our sensors employ a thermal bridge or MEMS-based thermal transit-time principle, where a micro-heated element measures the heat transfer rate in flowing oil. As viscosity affects how efficiently heat moves through the fluid, the sensor can accurately infer real-time kinematic viscosity changes—vital for understanding oil degradation and fuel dilution.

Our Software ASTER

ASTER is Sensyn’s flagship software platform designed to act as the central nervous system of your onboard oil condition monitoring infrastructure. Installed in the Engine Control Room (ECR), or Monitoring room ASTER provides a unified interface to visualize, analyze, and manage data from multiple LOTUS Beacons across your machinery systems.

Whether monitoring a single engine or an entire fleet of auxiliary units, ASTER makes it easy to access real-time health data across critical parameters—viscosity, density, dielectric constant, water content (aw and ppm), temperature, wear debris (Fe/NFe), and more.

ASTER Portal

ASTER PC is Sensyn’s onboard software application designed for real-time oil condition monitoring from the heart of the ship—the Engine Control Room (ECR). It provides engineers with a live, intuitive dashboard to monitor critical parameters like viscosity, water content, dielectric constant, temperature, and wear debris across multiple machinery units. ASTER PC supports customizable threshold alerts, MSDS-based oil configuration, and equipment-specific profiling, enabling proactive responses to emerging issues. With local data access, USB update support, and Modbus RS485/TCP integration, ASTER PC is a plug-and-play solution that works seamlessly even in offline environments, ensuring crews have the visibility they need to protect vital equipment without relying on external connectivity.

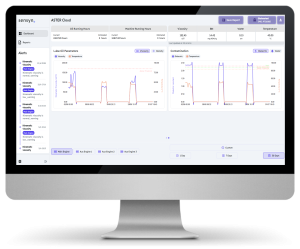

ASTER Cloud

ASTER Cloud complements ASTER PC by offering a cloud-based platform for remote analytics, centralized fleet monitoring, and long-term data management. It enables shipowners, technical teams, and fleet managers to view oil condition data from multiple vessels through a secure web portal—anytime, anywhere. ASTER Cloud supports historical trend analysis, automated reporting, fleet-wide benchmarking, and centralized alert management, helping teams make smarter maintenance decisions from shore. With optional API and SCADA integration, it connects directly to your existing digital infrastructure, turning onboard sensor data into actionable insight across your organization. Together, ASTER PC and ASTER Cloud form a powerful ecosystem that bridges onboard monitoring with shore-based intelligence.

Analytics: Turning Data into Actionable Intelligence

The Analytics component of LOTUS is designed to deliver precise, actionable insights to ensure optimal machinery performance and oil quality management. Here’s how LOTUS Analytics transforms data into value